Heavy Vehicle Starter Motors

An engine with a capacity of more than 3 L requires a large starting motor, specifically for a compression-ignition (CI) engine. CI engines must be cranked at a speed of at least 100 rpm to initiate combustion. Due to a very high compression ratio in CI engines, the maximum torque required is greater than a petrol engine.

The high pressure in the cylinder accelerates the piston rapidly during its downward movement. This causes considerable variation of both the rotational speed and the resisting torque loading on the starter motor.

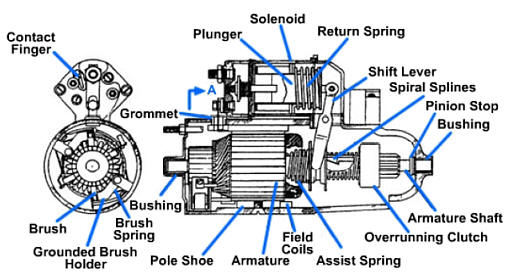

To achieve high starting power heavy vehicles normally use a 24 V system. For a given electrical power requirement, the doubling of the voltage compared with a 12 V systems, reduces the current by half. Without the extra 12 volts, the current load on the battery and starter circuit becomes exceptionally high, especially on a cold morning in winter. Another problem associated with large engines is the requirement of high torque to overcome breakaway and inertia of the heavy parts. It also needs a strong drive system and the pinion of this system must be fully meshed with the ring gear before the motor is fully powered. Two types of motor and drive system in use are axial (sliding armature), and coaxial (sliding gear).

Tips from:http://what-when-how.com